First Chain On the Dome - Set With Refractory Mortar - August 2024

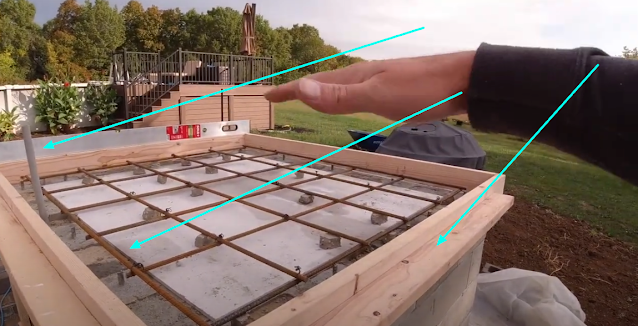

Back a couple weeks ago, I shared the latest pizza oven build project update: I set the floor and the first chain of the dome . I went with an isolated floor, so the first 'chain' of the dome is set at the same height as the floor. But, instead of being set on a 50/50 blend of mason's sand and fireclay, I set the dome chain with refractory mortar - BETWEEN - the joints. Today, I'm sharing how the dome is going vertical. Thanks to my brother-in-law (not Equation Boy/Man, rather on Nat's side), I have an indispensable tool (IT) or dome gauge that allows me to easily set each brick of the dome at the right distance and angle. You can see it in the first photo below. The other thing that I did was to cut-down the Masonite template that I used to create the floor and placed it *inside* the dome to keep the floor clean from errant mortar and what-have-you. I'll pull it out when the dome is complete. The first photo shows ...

.jpg)

.jpg)