Pizza Oven Progress - One Of The Sidewalls Installed - September 2025

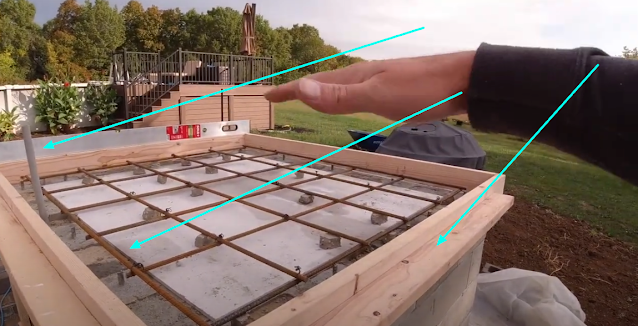

The last time that I posted about our backyard pizza oven was earlier this Summer in Late May when I showed a long burn in the brick chamber . But, that doesn't mean progress hasn't been made on completing the build. Despite some setbacks and the heat of the Summer, I've moved along with my DIY build and have been working to build the enclosure. That requires walls and a roof. Both are underway. But, the photo below shows a milestone: one of the sidewalls is now completely enclosed. The corners are built from concrete blocks and the middle section is now covered in fire-resistant concrete board. I will post the details of the enclosure build (including the concrete blocks) and the roof. The next step that I'm facing is to close in the other three faces. Then, pour in some loose insulation. And, finally...finish the roof.

.jpg)